Pipeline Rehabilitation Made Easy

Primus Line® Rehab is an innovative technology for the trenchless rehabilitation of pressure pipelines for different media such as gas and oil. This technology offers you a safe, reliable, and sustainable solution for trenchless rehabilitation of pressure pipes. The process is based on a flexible high-pressure liner and a connection technology developed specifically for this system.

The Primus Line Flexible Rehab Pipe is suitable for the transportation of various liquids and even has drinking water approval in many countries.

The ideal flow characteristics due to a smooth inner coating and the optimized systems for high, medium and low-pressure requirements make Primus Line® Rehab an economical solution for the rehabilitation of aging pipelines. In this way, network operators benefit from reliable operation and a sustainable investment in their assets.

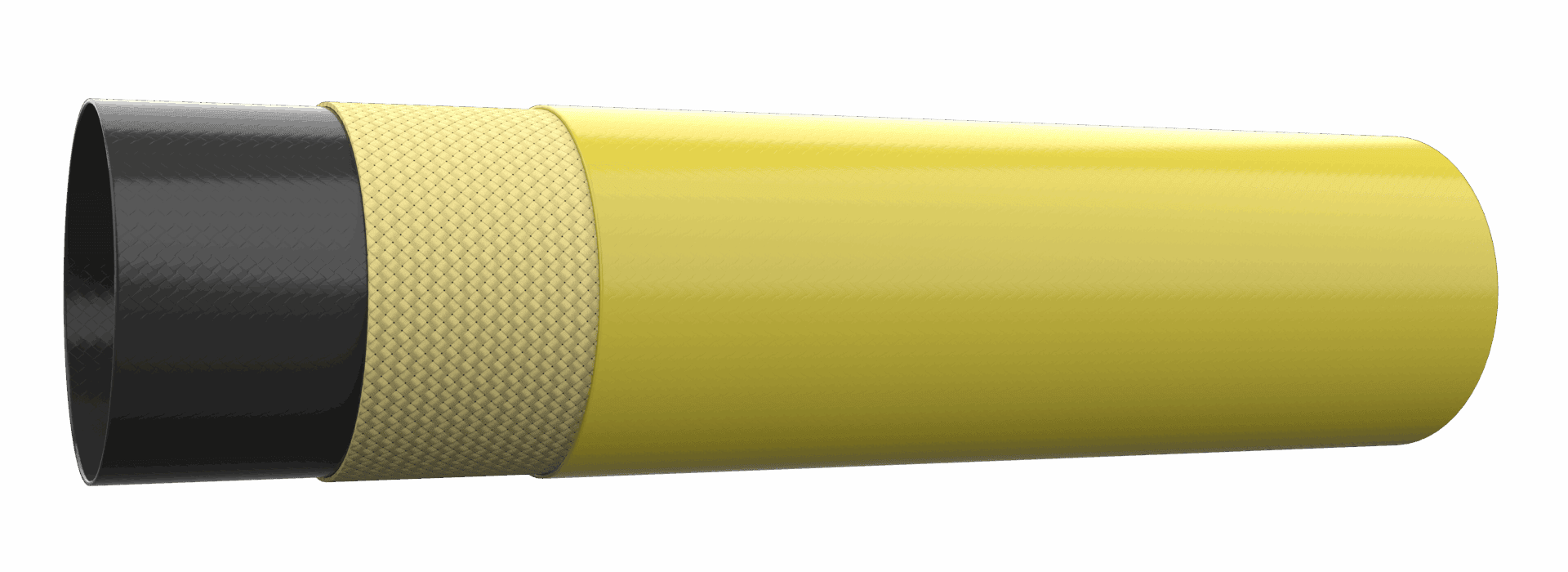

Composite Liner

Technical Details:

Available in nominal diameters from DN 150 to DN 500 / from 6 inches to 20 inches

- Maximum operating pressure depending on diameter: 82 bar to 12 bar / 1189 psi to 174 psi

- Design values for temperatures greater than 30 °C / 86 °F and, under certain conditions, up to 60 °C / 140 °F

- Design values for installation around bends

- Friction coefficient: k = 0.028 mm

Inner Layer

Polyethylene (PE) or thermoplastic polyurethane (TPU), depending on the transported medium

- Hygenic

- High abrasion resistance

- High chemical resistance

Reinforcement

One- or two-layered Kevlar® fabric, depending on the required pressure rating

- Accommodates operating pressure by itself

- Up to 10 times stronger than steel of equal weight

Outer Layer

Polyethylene (PE) or thermoplastic polyurethane (TPU)

- High abrasion resistance, protecting the fabric during installation and operation

Liner Types

OIL

Inner layer: TPU

Reinforcement: Seamless, woven aramid (one- or two-layer) fabric

Outer layer: Abrasion-resistant PE sheath

Wall thickness: 6 mm / 8 mm

0.24 inches / 0.31 inches

Suited for the following media / fields of application. Other media only after detailed review and approval.

- Crude oil

- Refined petroleum products

- Process water mains

- Diesel

- Jet A1

- Kerosene

GAS

Inner layer: TPU

Reinforcement: Seamless, woven aramid (one- or two-layer) fabric

Outer layer: Abrasion-resistant PE sheath

Wall thickness: 6 mm / 8 mm

0.24 inches / 0.31 inches

Suited for the following media / fields of application. Other media only after detailed review and approval.

- Natural gas

- Coke gas

- Methane

- hydrogen (H2ready certified)

- Propane

- Butane

- Oxygen

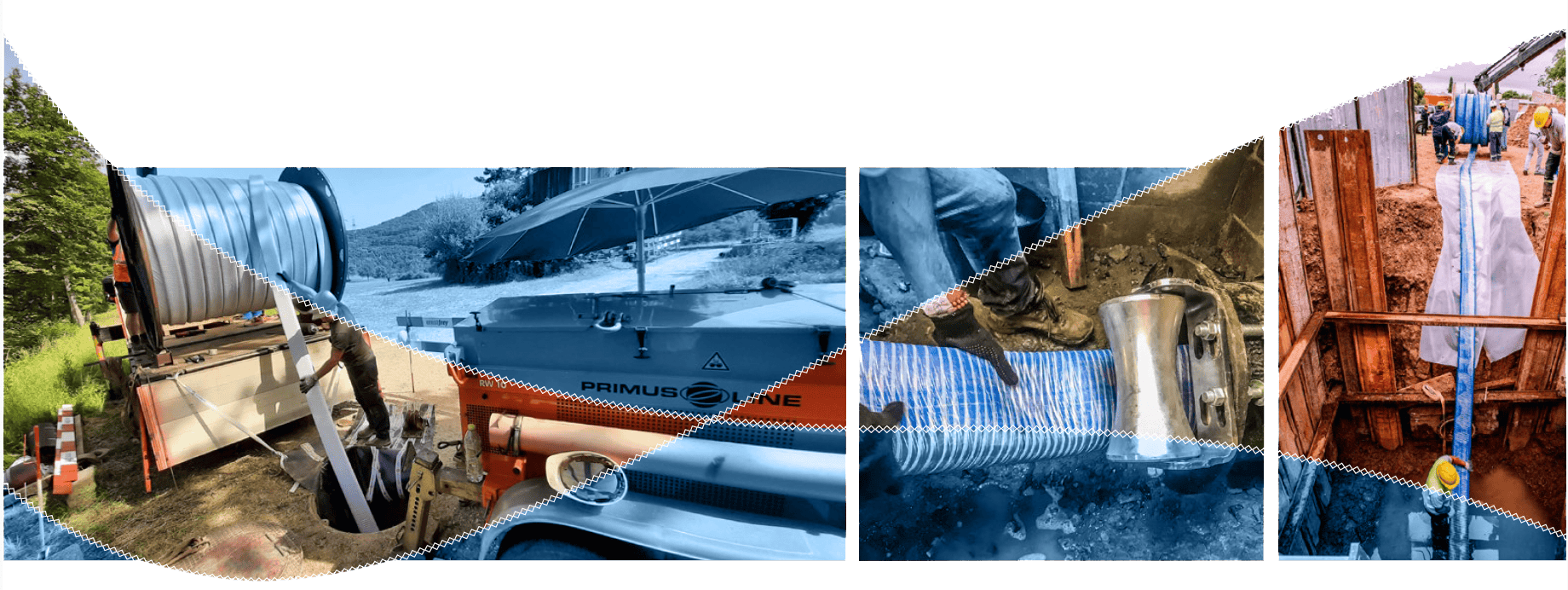

Fast and Easy Deployment

SUITs most ENVIRONMENTS

Pipelines often run through environments that are hard to access. Obstacles to an easy and fast rehabilitation of aging pipes can be of geographical, economical, architectural or environmental nature.

Installation only requires small excavation pits at the beginning and end of the section to be rehabilitated. Existing manholes can also be used. This speeds up the work, protects the environment, and significantly reduces the CO2 footprint.

SUITABILITY OF PRIMUS LINE®

Primus Line® is suitable for a quick and reliable rehabilitation of pressure pipes between DN 150 and DN 500 / 6 inches to 20 inches. Thereby, several bends can be traversed while achieving installation lengths of up to 2,500 m / 8,200 feet.

Reliable and Versatile

Our oil and gas pipe rehab stands for the fast and reliable rehabilitation of pressure pipelines. Several bends can be traversed, and installation lengths of up to 8,200 ft. can be implemented with only a small amount of machinery. This makes the system ideal for use in environments with high geographical, economic, architectural, or ecological requirements.

Cost Advantage

- Installation speeds of up to 10 meters per minute

- Up to 2,500 meters / 8,200 feet per pull

- Quick re-commissioning for short downtimes

- Low pre-investment for installers

- 50+ years of service life

Sizes & Transport

This system is available in sizes DN 150 to DN 500.

The flexible pipe is coiled in U-shape onto specialized transport reels and delivered to the customer. Depending on its diameter, a single reel can accommodate up to 4,000 metres / 13,120 feet of pipeline, efficiently fitting onto a single truck. This approach minimizes both logistics costs and the environmental impact associated with transport.

Applied Worldwide

Puerto Barrios Terminal, Guatemala

Transported medium: refined petroleum products

Project length: 2,200 feet

Old pipe: uncoated carbon steel / 10 inches

- Installation time: 7 working days

- Total replacement of the pipeline was not an option due to incoming vessels having strict schedules.Primus Line was the best option.

Odfjell Refinery, Houston

Transported medium: sanitary sewer effluent

Project length: 16,000 feet

Old pipe: cast iron / 6 inches

- Installation time: 4 weeks

- One third of the cost and time that conventional CIPP methods

Along with a successful installation, the client also reported an increase in flow rate.

Certifications

ISO 9001:2015 – Quality management system

ISO 14001:2015 – Environmental management system

ISO 45001:2018 – Occupational health and safety management system

ISO 50001:2018 – Energy management system

Ready to start your Pipe Rehabilitation?