Rehabilitation

Epoxy Coating & Pipe Relining

Underground Technology

INNOVATIVE Solutions

Innovative

Solutions

Hill Services is committed to providing innovative solutions to the industry across the Mid-South where our long-term relationships are based on integrity + reliability. Our comprehensive approach to designing, building, maintaining and servicing mechanical systems makes us a preferred partner in the industry. Your company is dependent on systems and equipment that operates smoothly and efficiently, and we got you. Our highly skilled project managers and technicians quickly assess your needs and develop solutions that work.

Pipe Lining

Pipe Lining

No dig, no problem

When main lines leak or corrode, they can damage above ground surfaces, cause pollution, and start severe flooding in treatment or industrial facilities. Hill Services uses various trenchless technologies to combat these and other problems caused by Inflow and Infiltration (I&I), including:

Hill Services uses the most technologically advanced methods of Cured in Place Piping (CIPP), including Inversion, Pull in Place and Point Repair for drain lines ranging from 3” to 72”.

Hill Services installs CIPP liners that are able to withstand heat, caustics and high pressure, commonly found in Industrial settings.

Pressure Pipe Lining

Pressure Pipe Lining

No dig, no problem

Hill Services rehabilitates buried pipelines (such as sewer, water, or natural gas pipes) without the need for a traditional “open cut excavation). “Launching and receiving pits” replace the trench needed by conventional excavation methods. Hill Services rehabilitates all different types of pressure pipelines from 4” to 20” with deployments of up to 5000 foot pulls for oil, gas, water, and process lines.

Pressure Pipe Lining

Pressure Pipe Lining

Hill Services rehabilitates buried pipelines (such as sewer, water, or natural gas pipes) without the need for a traditional “open cut excavation). “Launching and receiving pits” replace the trench needed by conventional excavation methods. Hill Services rehabilitates all different types of pressure pipelines from 4” to 20” with deployments of up to 5000 foot pulls for oil, gas, water, and process lines.

Equipment: 5 Key Pieces

- 1. Expander head

- 2. Pulling rods

- 3. Pulling machine

- 4. Retaining device

- 5. Hydraulic power pack

Methodology

Less Disruption, Cleanup and Cost

Always consistent

Place Piping

Cured In Place Piping (CIPP)

More customer satisfaction, needs met, and quality control

- Returning production to the drain line sooner

- Quality Control

- Safety a Top Priority

How it works

A resin-saturated felt tube made of polyester is inverted or pulled into a damaged pipe. It is usually done from the upstream access point (manhole or excavation). Little to no digging is involved in this trenchless process, making for a more environmentally friendly method than traditional “dig and replace” pipe repair methods. The liner can be inverted using water or air pressure. The pressure required for inversion can be generated by using pressure vessels. Hot water, ambient cured or steam is used to cure the resin and form a tight-fitting, joint-less and corrosion-resistant replacement within a pipe. Service laterals are restored internally with robotically controlled cutting devices. The rehabilitated pipe is then inspected by closed-circuit television (CCTV).

Why we do it

- More economical than traditional excavation

- Allowing critical production to resume more quickly

- Less disruptive compared to traditional excavation

- More environmentally friendly compared to traditional excavation

Some benefits of our CIPP Inversion Process:

- Formulated Epoxy Resins

- Stop Inflow and Infiltration (I&I)

- Re-Line 22’s, 45’s & Sweeping 90’s

- NSF Standard 14 Approved

- Eliminate Root Intrusion

- Bridge Missing Pipe Sections

- Minimum Design Life 50 Years (Tested)

- Prevent Pipe Failure

- Reline Different Size Transitions

- Seal Open Joints

- Single Point of Access for Lining

- Non-Woven / No Stretch Liner

- Increase Flow Efficiency

We offer the following in trenchless technology

- Air pressure continous Inversion up to 1,000’ runs

- Pipe diameters of 2” to 60”

- Pull in Place liners

- Point repair installations

- Negotiating multiple blends or turns in piping

- Robotic reinstatements up to 24” in diameter

- Stream, ambient curing

- Hot water curing

- IAPMO Certified

- CIPP

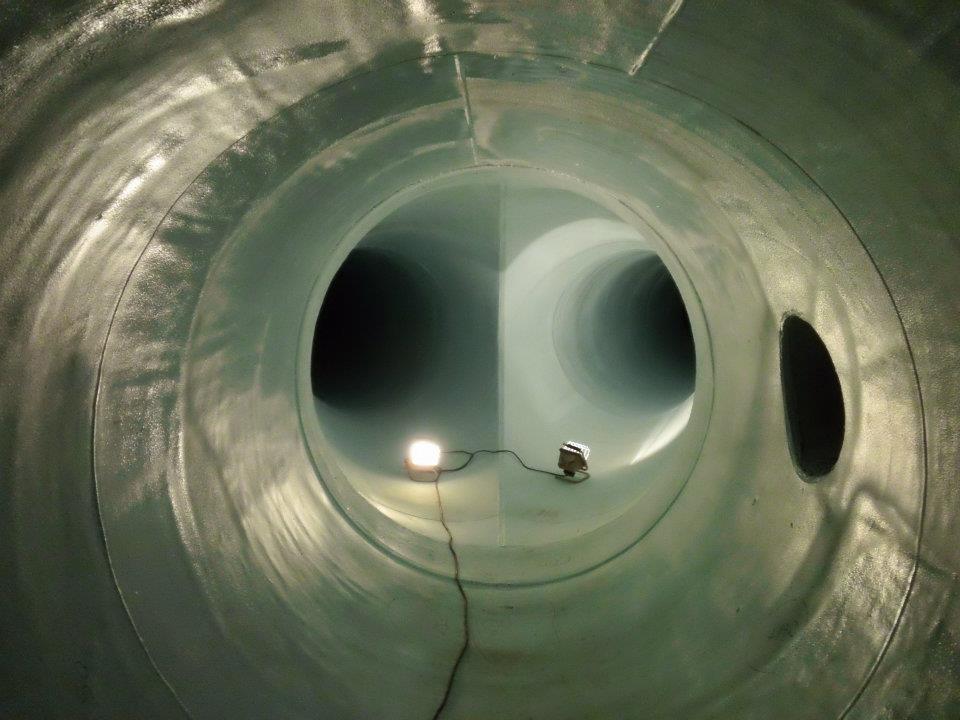

Epoxy Coating

Epoxy

Coating

Leaking tanks, vessels or Inflow & Infiltration (I&I can be problematic, affect production and costly.

By applying 100% solid epoxy coatings to these surfaces. Hill Services can restore them prolonging their life expectancy and getting your company back to full production faster,

What are the benefits?

- Durable and Chemical Resistant

- Good Moisture Impact Resistant

- Cost Effective & Versatile

Manhole

Manhole Rehab

Our manhole rehabilitation specialists can solve your manhole Inflow and Infiltration (I&I) problems; restoring your structures to “better than new” condition in less time than it would take to replace them — and for a fraction of the cost.

Epoxy

Our technicians use a wide range of 100% solids, zero-VOC epoxies to meet your exact requirements. These ultra high-build products can be sprayed or troweled-on to achieve a 1/4 inch (250 mil or greater) wet-film thickness-on vertical or overhang surfaces without sagging. They are modifiable to meet specific flexural modulus and strength, cure fast even under water, and provide premium corrosion resistance where high concentrations of hydrogen sulfide, sulfuric acid, sodium hydroxide, hydrocarbons and an array of other chemicals are present.

Video Inspection

Hill Services Pipeline Video Inspection Equipment with High definition, pan & tilt capabilities along with a digital video, log observations, generated reports and directly linked to asset-management software. With our Pipeline video inspection equipment, Hill Services can video inspect Drain Lines from 2” to 72” in diameter.

We cover Nuclear, Oil & Gas and heavy industrial and manufacturing sectors. Our video inspection CCTV Rovers/Cameras can be used in drain pipes ranging from 2”-72”, Lengths up to 5,000 Linear Feet with 45 and 90-degree bends, and to deepest pipelines of 50 feet.

Our Video Inspection reports help determine the overall condition of the existing host pipe, Identify (I&I) Inflow & Infiltration/Premature Failures, Diameter size, length & pipe type. Hill Services will provide a complete written video inspection report with Pipeline Mapping & Video Record documentation provided upon completion of the project